Enabling Aviation’s Transition to Net-zero Emissions

February 10, 2023 | Topics: Battery Test, Fuel Cell, Sustainable Energy

How EA Elektro-Automatik supports the future of hydrogen-fueled airplanes with electric propulsion systems

An exciting aspect of engineering is being part of a transformation in how people live their lives through new innovation. Certainly, this is true of moving to hydrogen-powered and battery-powered commercial flight. Futurists, electrical engineers, and aviation engineers envision a world of quiet, zero-emission airliners, drones and even autonomous air taxis.

The motivation for achieving net-zero emissions in flight goes beyond the ability to meet greenhouse gas reduction mandates. Like electric cars, electric motors are expected to have far lower maintenance costs than their kerosene-powered counterparts. The operational cost-savings are expected to make short-haul flights more profitable, opening up new airline routes.

Small airplanes may be all-electric. According to ResearchAndMarkets.com, the size of the global Electric Aircraft Market size is expected to reach USD 226.6 Million in 2030, and major airlines have announced plans to fly electric planes by that same year. Engineers are moving swiftly to bring this technology to aviation by leveraging what has already been developed for hybrid and electric automobiles.

Ready to Get Started? Request a Quote

Some large aircraft are also under development that will rely upon hydrogen fuel cells to provide the electric power needed for propulsion. Companies like ZeroAvia have designs in the test flight phase.

Whether a plane uses hydrogen or is all-electric, its development presents a host of engineering challenges. For aviation engineers leading the initiatives, the task is more complex than what is faced by their automotive electric vehicle counterparts. First, a plane with an electric propulsion system requires substantially more power than a car, and second, the reliability and safety requirements are extreme. A system failure at 30,000 feet is obviously more consequential.

Rising above technology barriers

In tomorrow’s airplanes, sustainable fuel and power systems will require entirely new DC electrified charging and propulsion systems rather than today’s mix of DC and AC power solutions.

Here are some of the many electrical technology barriers that electrical aviation will have to overcome:

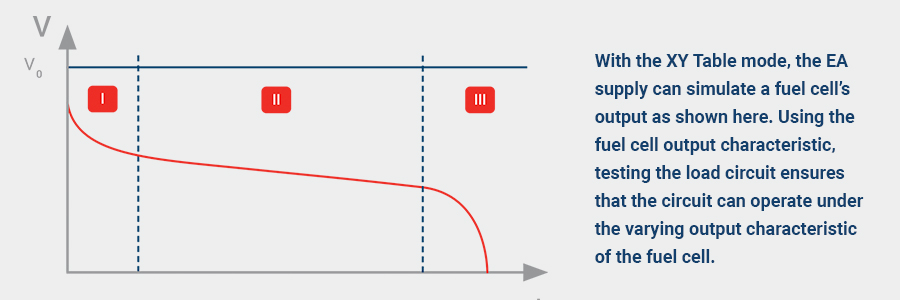

- New energy supply and storage systems, including fuel cell battery management. These systems must provide clean, smooth power, especially during peak take-off demands. (See our application note, Fuel Cell Simulation.)

- Lighter and smaller engines and battery power systems

- A range of power conversion and power distribution systems to convert main DC supply grid levels of 700-1000V into lower ranges for instrumentation (28 VDC), air conditioning (400 VDC), or critical landing gear/wing control/braking systems (±270 VDC)

- Designing for extreme environmental conditions, ranging from vibration, temperature changes, humidity, and high acceleration/gravity conditions

Inventing new power and test routines in DC power supplies

Each new electronic system and device must be thoroughly tested for performance, reliability, EMI interference and safety. These include high-power electric propulsion motors having megawatt peak power, DC motors to operate heavy equipment such as landing gear and wing flaps, and batteries with enough capacity and efficiency for long-distance flights. Fortunately, EA Elektro-Automatik is an expert at the power supply and load technologies needed to innovate aviation power systems, including equipment that is “future-proofed” to accommodate changes.

Testing the future of flight

EA Elektro-Automatik offers a range of power conversion products to properly test all these electrical and electronic devices and networks. To start, our products are capable of high-power aviation applications:

- Power ranges of 320W up to 3.84MW

- Voltage ranges of 0-60 VDC to up to 0-2000 VDC

- Current ranges up to 64,000A

Beyond raw power, EA products have features that make them particularly well-suited for demanding aviation electrical test routines.

- True Autoranging Capability. This feature allows engineers to test a greater range of devices by delivering full power output over a wide range of voltages and currents. Unlike conventional power supplies, an EA autoranging power supply can provide full power output down to 1/3 of its maximum voltage and current. As a result, EA can often provide a lower-power DC supply for a given load requirement. This saves test rack space and cooling requirements, which enables lowers cost ad simplifies the test system. (See our technical note on the theory of auto-ranging.)

- Bidirectional Regenerative Power Supplies. EA Elektro-Automatik’s bidirectional DC power supplies are regenerative in sink mode so that the energy extracted from the device under test is recovered and sent back into the grid with 96% efficiency. This regenerative loads feature pays for itself in energy cost savings.

- Built-in Function Generator. In contrast to conventional power supplies, engineers do not need to connect an external signal generator to modulate the power supply output.

- Electronic Regenerative Loads with Energy Recovery. EA electronic loads with the same autoranging, function generator, and regenerative energy recovery features are ideal for testing the fuel cell power source. The electronic load can simulate a wide range of states of the load, including failure states, to ensure the fuel cell can output the necessary power and safely respond to any operating mode of the load.

A legacy of aviation experience

Using EA Elektro-Automatik power supplies and electronic loads, engineers can test in the lab the DC systems that will power the future in avionic innovation. Whether the application is an airplane, drone or unmanned aerial vehicle, we bring a track record of expertise in the world’s most rigorous test routines and commercial/military standards. Building on our position as Europe’s leading manufacturer of programmable power supplies, EA Elektro-Automatik is proud to support the world’s most innovative engineers to create a greener world.